Lean Sustainability: The Future of Eco-Efficient Business

At VA Innovation, we believe that combining lean thinking with sustainability is the key to building efficient, eco-friendly businesses. This page provides a comprehensive guide to lean sustainability, blending an approachable introduction with actionable insights, detailed examples, and advanced practices.

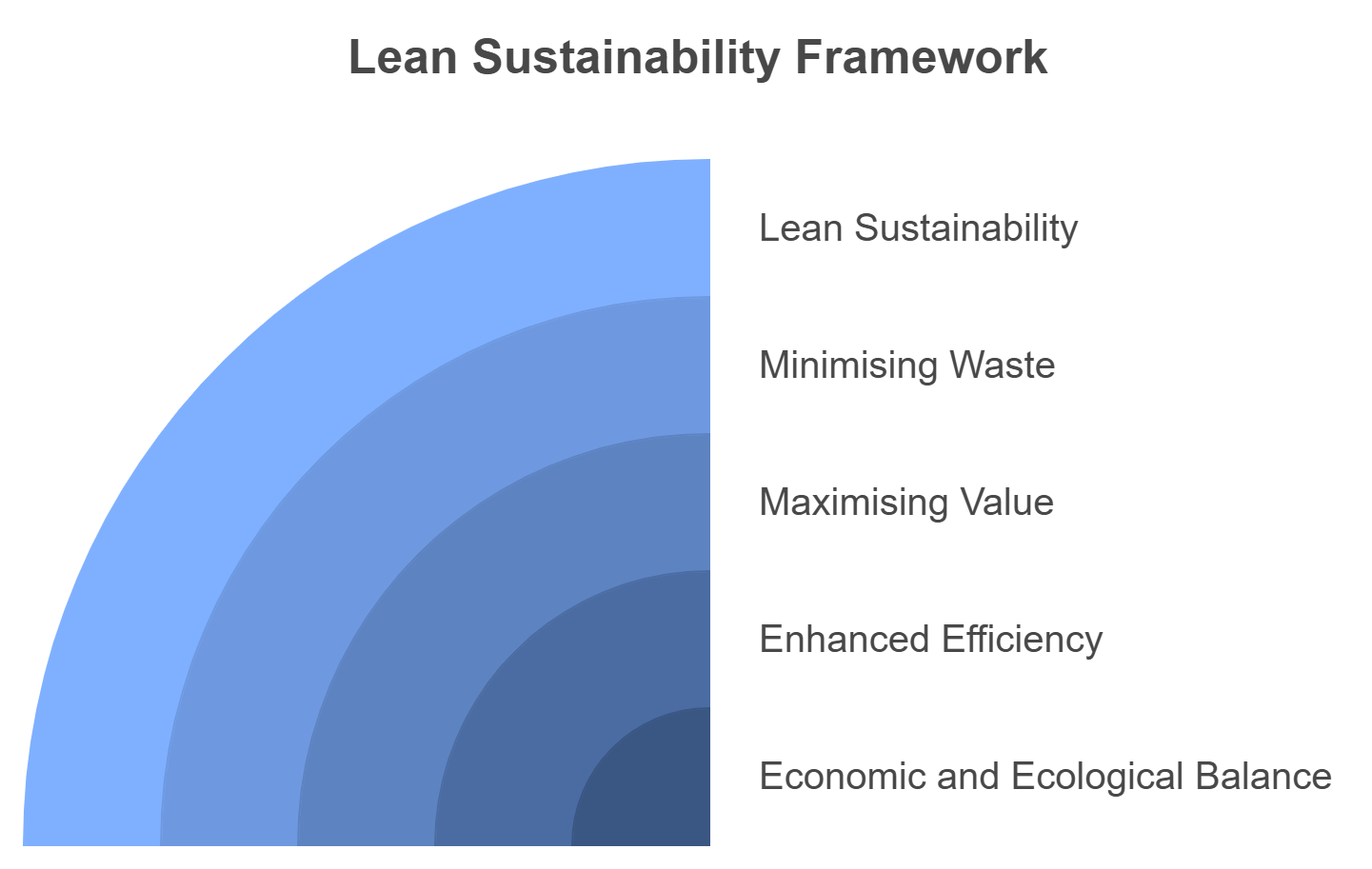

What is Lean Sustainability?

Lean sustainability integrates the principles of lean thinking—reducing waste and improving efficiency—with environmental sustainability, focusing on minimising ecological impact. It’s not just about cutting costs or streamlining processes; it’s about ensuring that your business operations are eco-efficient and socially responsible.

Why is Lean Sustainability Important?

Key Benefits

- Cost Savings: Reduce unnecessary energy use, materials, and other operational inefficiencies.

- Environmental Impact: Minimise pollution, conserve resources, and contribute to a sustainable future.

- Competitive Advantage: Build trust with eco-conscious customers and stakeholders.

- Regulatory Compliance: Stay ahead of environmental regulations to avoid fines and penalties.

Core Principles of Lean Sustainability

Identifying and Eliminating Green Waste

Green waste refers to inefficiencies that harm the environment, such as excessive energy consumption, emissions, or poorly managed materials. Tools like value stream mapping and Gemba Walks help organisations pinpoint these wasteful practices and develop strategies to address them.

Using Lean Tools for Sustainability

Traditional lean tools can be adapted to drive sustainable outcomes:

- 5S Framework: Organise and optimise workplace environments to reduce waste and improve energy efficiency.

- Data Analysis: Quantify energy use, emissions, and material waste to find improvement opportunities.

- Kaizen (Continuous Improvement): Implement small, ongoing changes that add up to big sustainability wins over time.

Moving Toward a Circular Economy

Lean sustainability aligns perfectly with the concept of a circular economy, where resources are reused, recycled, and reintegrated into the production cycle. This reduces reliance on finite resources and supports long-term sustainability.

Real-World Applications

Manufacturing

A large manufacturing company reduced material waste by 30% using lean tools like value stream mapping. By optimising production processes, they not only saved on raw materials but also significantly cut their carbon footprint.

Food Packaging

At VA Innovation, we worked with a food packaging business to identify shop floor waste. By applying the 5S framework and process mapping, the company reduced material waste by 20% and improved recycling practices, aligning with their sustainability goals.

Data Centres

A global data centre used Lean Six Sigma techniques to optimise its cooling systems. By tracking energy usage and implementing efficient airflow strategies, the centre reduced energy consumption by 40%, saving millions in operational costs annually.

Advanced Practices in Lean Sustainability

For businesses already familiar with lean sustainability, here are some cutting-edge strategies:

AI-Driven Waste Management

Leverage artificial intelligence to monitor and predict resource waste patterns. AI tools can track inefficiencies in real-time, enabling swift corrective actions.

Blockchain for Sustainable Supply Chains

Blockchain technology enhances transparency and accountability across supply chains, ensuring ethical sourcing and reducing environmental impacts.

Renewable Energy Integration

Integrating renewable energy sources into lean processes, such as solar or wind power, further reduces the environmental footprint of operations.

Why Choose VA Innovation for Lean Sustainability?

At VA Innovation, we combine practical lean tools with deep sustainability expertise. Here’s what sets us apart:

- Proven Results: Our clients have achieved measurable outcomes, such as a 20% reduction in waste and significant cost savings.

- Custom Solutions: We tailor our approach to your business, ensuring a perfect fit for your industry and goals.

- Expertise in Implementation: From Gemba Walks to advanced data analysis, we guide you through every step of your lean sustainability journey.

FAQs About Lean Sustainability

What is the difference between lean thinking and sustainability?

Lean thinking focuses on efficiency and eliminating waste in processes, while sustainability prioritises minimising environmental harm. Together, they create a powerful synergy that benefits both business and the planet.

How do I start implementing lean sustainability in my business?

Begin by evaluating your operations for green waste. Use lean tools like Gemba Walks and value stream mapping to identify inefficiencies.

VA Innovation can help you tailor strategies to your specific needs.

What industries can adopt lean sustainability?

Lean sustainability principles can be applied across industries, from manufacturing to logistics, food packaging, and beyond. Check out our Case Studies page to find out more

How does lean sustainability support a circular economy?

By reducing waste, improving recycling, and finding ways to repurpose materials, lean sustainability aligns with the goals of a circular economy, promoting resource efficiency and environmental stewardship.

FAQs About VA Innovation

Who is VA Innovation?

We’re a leading consultancy specialising in Lean Six Sigma, founded to help businesses improve efficiency, reduce waste, and achieve their sustainability goals.

What is your approach to lean sustainability?

We combine practical lean tools with a deep commitment to environmental impact, tailoring solutions that are both efficient and sustainable. Click here for our plan for achieving net-zero carbon emissions by 2050, in line with the UK Government’s Net Zero Strategy and the Paris Agreement.

How can I work with VA Innovation?

Simply visit our website at VA Innovation or contact us directly to schedule a consultation.

Take the First Step Toward Lean Sustainability

Lean sustainability isn’t just a concept, it’s a pathway to building a business that’s efficient, responsible, and future-ready. Whether you’re new to these ideas or ready to deepen your approach, VA Innovation is here to guide you.

Ready to transform your business? Contact us today to start your journey to lean sustainability!

Top Lean Six Sigma Reads: