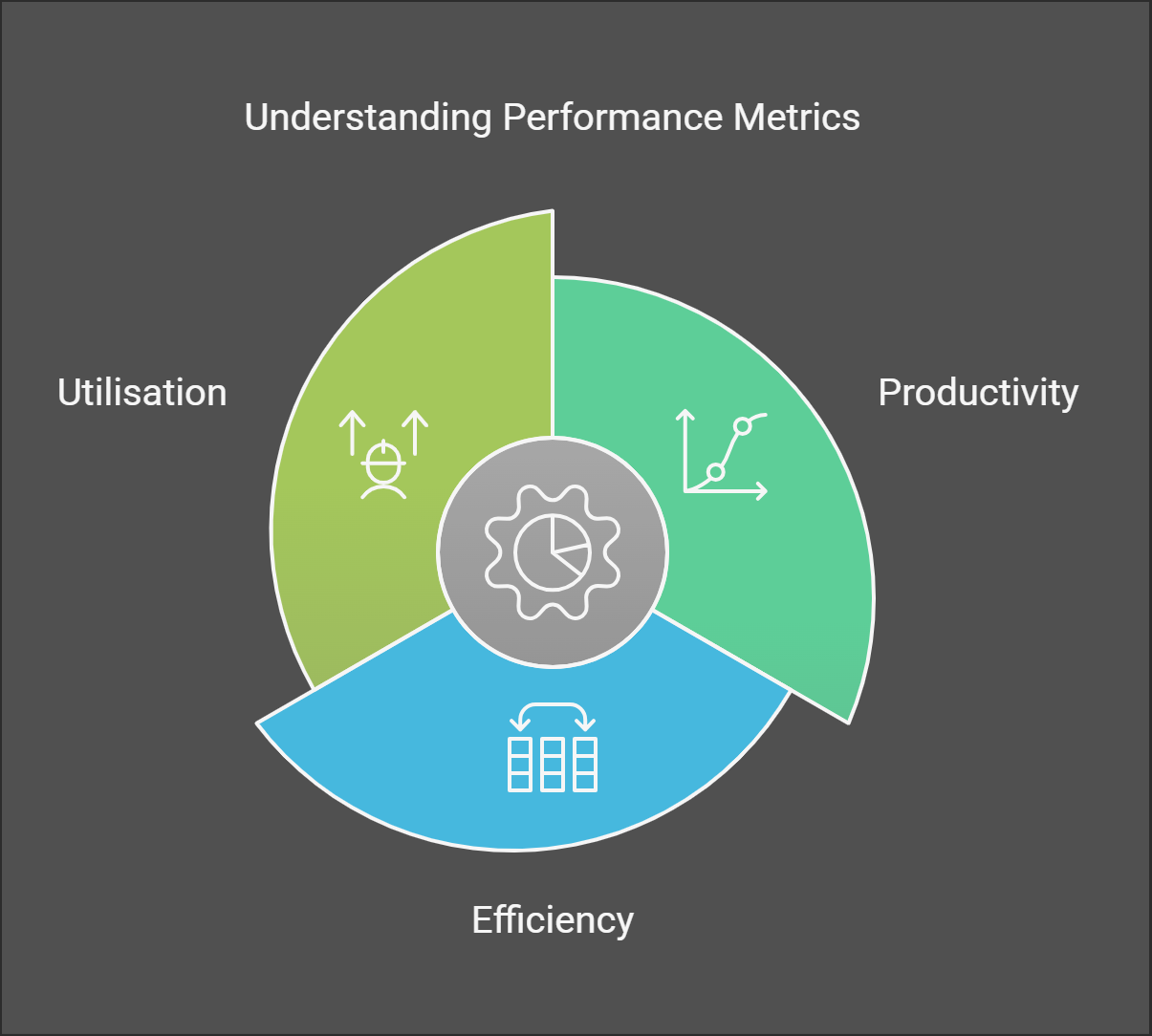

Understanding Performance Metrics and KPIs (Key Performance Indicators)

Productivity, Utilisation, and Efficiency Explained

At VA Innovation, we specialise in helping businesses optimise their processes to maximise output, reduce waste, and improve overall performance. In this blog post, we’ll break down three key performance indicators (KPIs) that every business should understand: Productivity, Utilisation, and Efficiency.

We’ll explain what they are, how they’re measured, and provide practical steps to improve them.

What Are Productivity, Utilisation, and Efficiency?

Productivity

Definition: Productivity is the rate at which output is produced per unit of input. In simpler terms, it measures how much work gets done relative to the resources used.

Formula: Productivity = Output / Input

Example: If a manufacturing line produces 1,000 packaged goods in 10 hours, productivity is 100 packages per hour.

The target for productivity will depend on the demand profile and industry. Have a look at Takt Time for more information.

How to Improve Productivity:

- Streamline workflows to eliminate bottlenecks.

- Train staff to perform tasks more efficiently.

- Invest in automation to reduce manual effort.

Utilisation

Definition: Utilisation measures the percentage of available resources that are actually being used for productive work. It helps businesses understand whether they are making the most of their workforce and equipment.

Formula: Utilisation = (Time Spent on Productive Work / Total Available Time) × 100

Example: If a machine runs for 6 hours during an 8-hour shift, the utilisation rate is (6/8) × 100 = 75%.

A good utilisation target for production facilities is 85%.

How to Improve Utilisation:

- Reduce downtime by implementing predictive maintenance.

- Improve scheduling to minimise idle time.

- Cross-train employees to increase flexibility in the workforce.

Efficiency

Definition: Efficiency measures how well resources are used to produce the desired output. It focuses on minimising waste while maximising productivity.

Formula: Efficiency = (Actual Output / Standard Output) × 100

Example: If a machine is expected to produce 500 units per hour but only produces 450, its efficiency is (450/500) × 100 = 90%.

A good efficiency target is anywhere from standard (60%) to world class (85%). Review Overall Equipment Effectiveness (OEE) for advanced manufacturing focused metrics incorporating quality.

How to Improve Efficiency:

- Identify and eliminate wasteful activities.

- Standardise processes to reduce variability.

- Use data-driven insights to fine-tune operations.

Key Differences Between Productivity, Utilisation, and Efficiency

| KPI | Focus | Key Question |

|---|---|---|

| Productivity | Output relative to input | Are we producing enough? |

| Utilisation | Resource usage vs. availability | Are we using our resources fully? |

| Efficiency | How well resources are used | Are we reducing waste and maximising value? |

Actionable Steps to Optimise Your Business Operations

1. Track and Measure KPIs Regularly

You can’t improve what you don’t measure. Monitoring key metrics will help identify areas for improvement.

2. Improve Training and Standardisation

Empower your workforce with the right skills and standardised processes to reduce errors and variability.

3. Leverage Technology for Better Insights

Automation tools and data analytics can provide valuable insights into inefficiencies and areas for improvement.

4. Implement Lean Six Sigma Techniques

At VA Innovation, we specialise in Lean Six Sigma consulting to help businesses streamline their operations and reduce waste effectively.

FAQs About Process Efficiency

What is process efficiency?

Process efficiency refers to how effectively a process converts inputs into outputs while minimising waste and maximising productivity.

How can businesses improve process efficiency?

- Automating repetitive tasks

- Reducing unnecessary steps in workflows

- Training employees on best practices

- Using data-driven decision-making

What are the main causes of inefficiency?

- Poor planning and scheduling

- Ineffective communication

- Lack of automation

- Unnecessary complexity in processes

How does Lean Six Sigma help improve efficiency?

Lean Six Sigma identifies and eliminates waste while improving quality and consistency in business processes.

Want to optimise your business processes and drive efficiency? Contact VA Innovation today! Visit our website at www.vainnovation.co.uk to learn more.

Top Lean Six Sigma Reads: