Theory of Constraints & Lean Six Sigma | VA Innovation

Welcome to VA Innovation’s comprehensive guide to the Theory of Constraints (TOC). Whether you’re a seasoned professional or just starting your journey to optimise business processes, this guide provides the insights and tools you need to eliminate bottlenecks, improve efficiency, and boost profitability.

What Is the Theory of Constraints (TOC)?

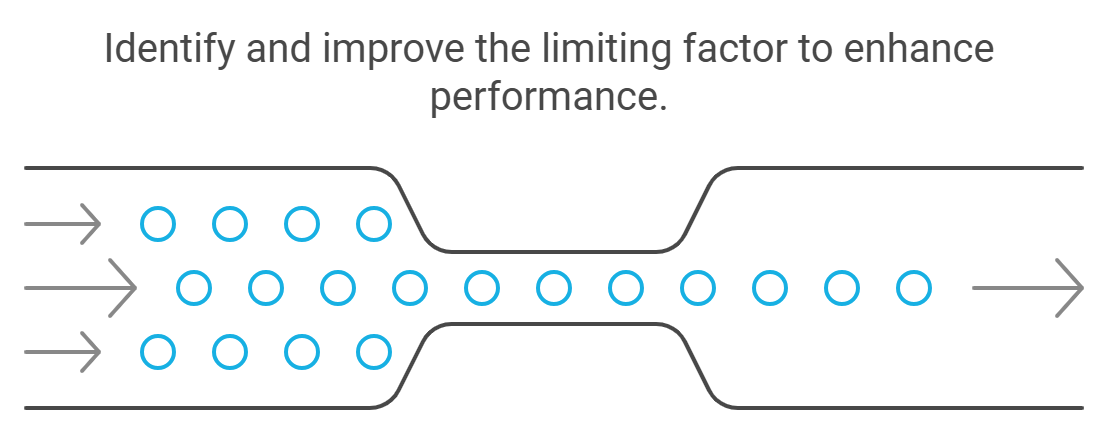

The Theory of Constraints, introduced by Dr. Eliyahu M. Goldratt, is a problem-solving and process improvement methodology. At its core, TOC helps businesses identify and address the weakest part of their operations, the constraint, so the entire system can function at its best.

Think of your business like a chain: the strength of the whole depends on its weakest link. TOC teaches us to focus on fixing that link for better overall performance.

Why the Theory of Constraints Matters to Modern Businesses

Every system has a limiting factor that restricts its ability to achieve goals. These constraints could be physical (like a slow machine), policy-related (such as outdated procedures), or even behavioural (such as a lack of training). Addressing these constraints can lead to significant improvements in:

- Operational Efficiency: Reduce downtime and optimise workflows.

- Customer Satisfaction: Deliver products or services faster and more reliably.

- Profitability: Increase throughput without major capital investments.

The Five Focusing Steps of TOC

TOC provides a structured approach to systematically improve processes. These are known as the Five Focusing Steps:

1. Identify the Constraint

Locate the bottleneck, the part of your process that limits overall performance. This could be a specific piece of equipment, a policy, or a skill shortage. Use a tool such as Value Stream Mapping.

2. Exploit the Constraint

Make the most of the existing constraint by using resources more efficiently. For example, schedule work to maximise the constraint's output.

3. Subordinate Everything Else

Align all other processes to support the constraint. Ensure non-constraint activities don't cause unnecessary delays or distractions.

4. Elevate the Constraint

If the constraint still limits performance, invest in a solution, this could mean upgrading equipment, hiring additional staff, or implementing new training programs.

5. Repeat the Process

Once a constraint is resolved, another will surface. TOC is an ongoing process of continuous improvement.

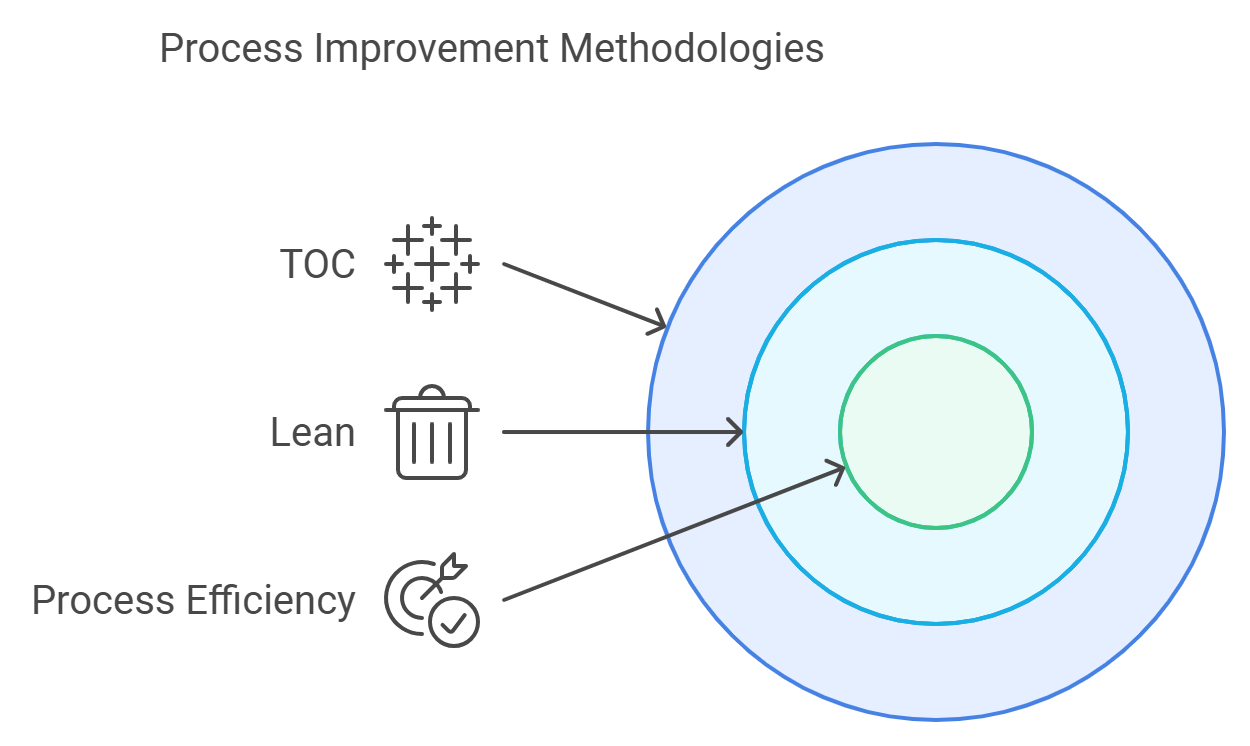

How TOC Aligns with Lean Thinking

TOC and Lean methodologies complement each other beautifully:

- Lean focuses on eliminating waste across processes.

- TOC focuses on resolving bottlenecks to improve throughput.

Together, they help businesses achieve streamlined, efficient operations with minimal resource waste.

Practical Applications of TOC

TOC isn’t just for manufacturing—it applies to a variety of industries:

- Operations Management: Identify delays on the shop floor and improve flow.

- Supply Chain & Logistics: Optimise inventory management and streamline deliveries.

- Project Management: Deliver projects on time by focusing on the critical chain.

- Sales & Marketing: Resolve barriers in the customer journey to improve conversion rates.

Real-World Example

Let’s say a food packaging company faces delays because one sealing machine works slower than the others. TOC would identify that machine as the constraint. The company might exploit the constraint by ensuring it runs continuously and subordinate other processes, like prepackaging, to match its speed.

Eventually, they could elevate the constraint by investing in a faster machine.

FAQs About the Theory of Constraints

What is the difference between TOC and Lean?

TOC focuses on resolving bottlenecks, while Lean aims to eliminate waste.

They complement each other and can be used together for maximum efficiency.

Can TOC work for small businesses?

Yes, small businesses often benefit greatly from TOC because it focuses on making the best use of limited resources.

Is TOC only for manufacturing?

Not at all! TOC applies to any system, whether it’s construction, aerospace, service industries, or even personal productivity.

Every process has a constraint; understanding what that is, is the key to making impactful improvements

What are the main types of constraints?

Constraints can be:

- Physical (e.g., equipment) an example would be throughput capped on how much a machine can process

- Policy-based (e.g., outdated procedures) i.e. a person is only allowed to process a certain amount due to a perceived decline in concentration levels or performance etc,

- Resource-related (e.g., lack of skills or staff) i.e. only enough time to manually complete a certain amount of tasks in the given time period.

How can I get started with TOC?

Start by observing where delays or inefficiencies occur in your process, this is often your constraint. Use process mapping to document it as a baseline.

Then follow the Five Focusing Steps to address it.

FAQs About VA Innovation

Who is VA Innovation?

We are a business consultancy specialising in Lean Six Sigma and process improvement. We’ve been helping businesses improve efficiency and reduce waste since 2021.

What services do you offer?

Our services range from Green Belt training to bespoke consultancy projects in Lean Six Sigma, Theory of Constraints, and operational improvement.

Do you work with businesses of all sizes?

Absolutely! We work with small businesses, large corporations, and everything in between.

How can I contact VA Innovation?

Visit our website at vainnovation.co.uk or get in touch through our contact form to discuss how we can support your business.

Take Action Today!

Are bottlenecks holding back your business? VA Innovation can help you tackle constraints, streamline your processes, and achieve your goals. Contact us today to learn more.

Top Lean Six Sigma Reads: