Kaizen: The Power of Continuous Improvement

What is Kaizen?

Kaizen is a Japanese business philosophy that means continuous improvement. It focuses on making small, daily improvements that add up to big results over time. Originally developed in Japan, Kaizen has become a global strategy for businesses looking to boost efficiency, reduce waste, and improve quality.

At VA Innovation, we help businesses integrate Kaizen principles into their operations to drive sustainable growth and success.

Why Kaizen Matters for Your Business

Many businesses struggle with inefficiencies, wasted resources, and low productivity. Kaizen helps fix these problems by encouraging:

- Employee involvement

- Optimising process flow

- Improving customer focus

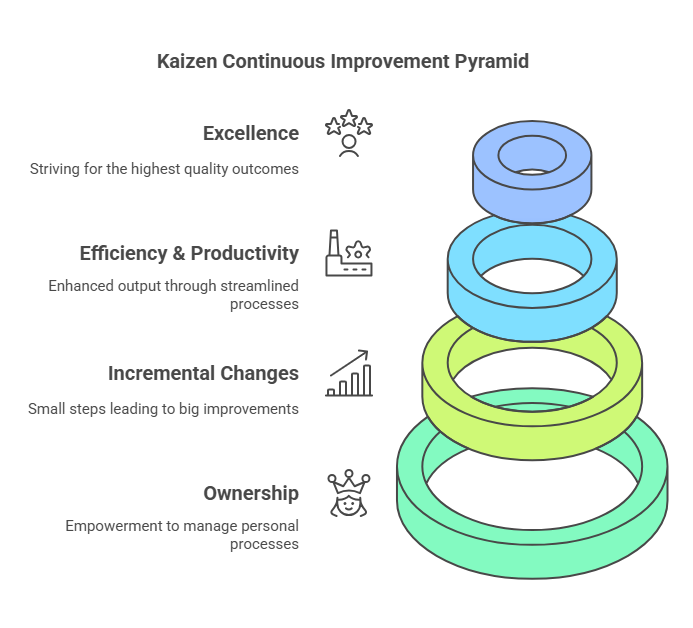

Key Benefits of Kaizen

- Boost Efficiency – Streamline processes and reduce unnecessary steps

- Reduce Waste – Eliminate wasted time, materials, and resources

- Enhance Quality – Improve products and services through small, continuous changes

- Increase Employee Engagement – Involve everyone in problem-solving and innovation

- Drive Sustainable Growth – Build a culture of improvement that lasts

Kaizen is not just a one-time project, it’s a mindset that helps businesses grow over time.

How to Implement Kaizen in Your Business

Applying Kaizen doesn’t have to be complicated.

Here are a few simple steps to get started:

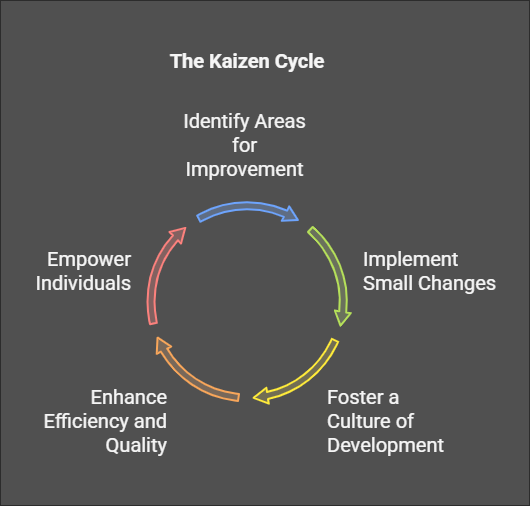

Step 1: Identify Areas for Improvement

Look at your processes and find small inefficiencies or bottlenecks. Ask your team:

What’s slowing us down? Where are we wasting time or materials?

Step 2: Use the PDCA Cycle

The Plan-Do-Check-Act (PDCA) cycle is a key Kaizen tool:

- Plan – Identify a problem and create a solution.

- Do – Test the solution on a small scale.

- Check– Measure the results.

- Act – If it works, implement it fully; if not, adjust and try again.

Step 3: Involve Your Employees

Your employees are on the front lines—they see inefficiencies daily. Encourage them to suggest small, everyday improvements and celebrate their successes.

Step 4: Track Progress and Keep Improving

Kaizen is a continuous process. Keep track of the changes you make, analyse results, and keep improving. It’s all about small, steady steps toward excellence

Real-World Kaizen Success Stories

| Company | Example |

|---|---|

| Toyota | Just-in-Time (JIT) manufacturing strategy is built on Kaizen. By making continuous small changes, Toyota eliminated waste, reduced costs, and improved production efficiency. |

| Boeing | Boeing incorporated Kaizen to refine its aircraft production, reducing defects and optimising workflows, which resulted in improved safety and reduced turnaround times. |

| Nestlé | Nestlé used Kaizen methodologies to improve operational efficiency in its supply chain, leading to cost reductions and enhanced sustainability initiatives. |

FAQs About Kaizen

Want to optimise your business processes and drive efficiency? Contact VA Innovation today! Visit our website at www.vainnovation.co.uk to learn more.

Top Lean Six Sigma Reads: